|

|

[The following is extracted from Application Note 19: New Fuel Control Strategies Enabled by Innovate’s “Direct Digital” Wideband Controls.]

Oxygen sensors are critical components in every internal combustion vehicle on the road. Innovate’s unique approach (aka “Direct Digital”) can be used to control oxygen sensors in a manner that differs greatly from traditional, mostly analog, technologies.

This, in turn, enables new strategies in fuel controls. While the initial commercial acceptance of the Innovate technology has been in the performance aftermarket, the biggest gains will be realized in the OEM market, where factory-original ECUs can be designed and programmed to utilize Direct Digital wideband technology.

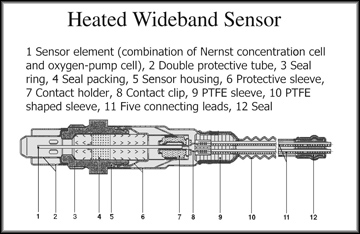

Current Innovate products use the same wideband zirconium-dioxide oxygen sensors as current production vehicles, but the control methodology is completely different. US Patent #6,978,655, titled “System, Apparatus, and Method for Measuring an Oxygen Concentration of a Gas,” fully details the inventions summarized below.

The Innovate measurement principle does not use the regular PID ( proportional-integral-derivative ) feedback mechanism to control the wideband sensor. Instead, the pump current is positive until the reference (Nernst) cell shows < Lambda 1 in the measurement chamber of the wideband. Then the polarity of the pump current is reversed until the reference cell shows > Lambda 1. This is done with a small hysteresis. This way the measurement gas in the measurement chamber oscillates at about 100-500 Hz around stoichiometric. The oscillation frequency depends on the constant (but changing polarity) pump current, hysteresis, the sensor itself, and Lambda. The frequency has a max at Lambda 1. This is basically a 2-point regulator, or in digital electronic terms, the operating principle of a delta-sigma analog to digital converter, except that here the analog value measured is directly the exhaust gas.

The fast response time of Direct Digital technology enables new fuel control strategies. The biggest impact is in two areas:

- Rapid load-transition Periods. Due to the slow response time of PID systems, even the most sophisticated modern vehicles must go “open-loop” for up to 500ms second after major throttle transitions (for example, “Acceleration Enrichment” period). Such open-loop operation often results in excessive fuel injection (and therefore reduced MPG, and increased emissions) during transitions. In most regular driving, transitions are quite frequent. It is estimated that eliminating open-loop operation acceleration enrichment improves average fuel economy by as much as 7%, and reduces emissions by the same amount.

- Injector balancing. OEMs allow up to 5% cylinder-to-cylinder variation in new fuel injectors. This is less than ideal to begin with, as some cylinders will be lean (producing excessive NOx), and some will be rich (producing excessive CO). The real problem however, is that this condition deteriorates over time (injector clogging, etc.). Cylinder-to-cylinder variation climbs to 10% or more, stressing the catalytic converter, damaging engines, and producing excess emissions. Direct Digital technology is fast enough to enable a single sensor to detect individual-cylinder lambda as the “slugs” of exhaust pass the sensor. This allows the ECU to vary each injector’s duty cycle, and precisely manage each cylinder.

The benefits of full-time closed-loop operation are clear- essentially you have a self-tuning, adaptive engine that can handle major variations in fuel composition, barometric pressure, and component aging. However, until Direct Digital, many of the gains from closed-loop operation were unattainable.

Designers of new fuel-control systems should fully explore the benefits of implementing full-time, closed-loop injection strategies based onInnovate's Direct Digital Wideband systems.

|

|